Lately there’s been a big push for workplace safety in material handling, warehousing and logistics. It’s not only on the part of government agencies like OSHA, but employers, consumers and industry organizations as well. Over the course of the last several years, the trend seems to have been for all of these different parties to converge on the idea that safety should be one of the primary concerns of those overseeing warehouse operations — right up there with managing efficiency and ensuring the warehouse contributes to profitability instead of detracting from it.

While different people from different industries and organizations will have widely varying opinions on how best to achieve a safer yet profitable warehouse environment, there will more than likely be some agreement about basic safety measures that can substantially increase safety while requiring minimal time and financial investments. A good example of this is pallet rack anchors, which should be used with virtually all pallet rack applications per ANSI/RMI requirements, and which are generally cheap and easy to use. Another great example that we’ll be covering more in-depth in this article is the flue spacer, an important but often neglected piece of the warehouse safety puzzle.

What Flue Spacers and Pallet Stops Do

What Flue Spacers and Pallet Stops Do

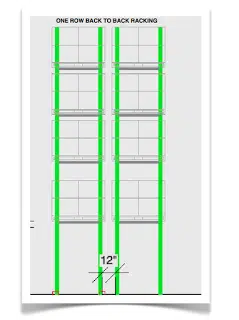

Flue spacers and pallet stops are closely related, and some flue spacers, such as the WorldStop by WorldWide Material Handling, do both jobs at the same time. In order to understand how this works, it’s important to know the definition of a “flue space.” In a pallet rack system, there are two types of flue spaces. The first type is referred to as a “longitudinal” flue space, and it can be described as the horizontal space between two rows of pallet rack. The second type is called a “transverse” flue space, and it can best be describeas the space between two loads on a pallet rack beam level. Why do flue spaces matter? The safety of an entire building and its occupants can depend on them.

In order for a warehouse’s sprinkler system to be effective should it ever have to be used, there needs to be a minimum amount of space in between objects that would obstruct the sprinklers’ ability to reach the lower levels. If a fire started on the ground level and there were no flue spaces in the warehouse, the water flowing from the ceiling would be rendered useless and the fire could spread more quickly. Having open spaces also allows the fire to vent vertically, slowing down the horizontal spreading of the fire. This is also one of the reasons why we typically encourage the use of wire mesh decks over solid decking, such as plywood.

When a pallet stop doubles as a flue spacer, it serves the dual functions of keeping pallets from being pushed off the rear side of the beam level while keeping a minimum longitudinal flue space maintained between rows of racking. When space gets tight and warehouse managers push for more inventory to be stored in less space, it can be critical to have a failsafe like flue spacers in place to keep flue spaces from being crowded out. Besides helping provide a baseline level of warehouse safety, flue spacers have secondary benefits as well.

Keeping Your Product Organized

In a fast paced and competitive warehouse culture, it can be easy for organization and order to play second fiddle to speed and throughput. And when more orders are moving and sales are up, this method can be hard to argue against. However, the two aren’t necessarily mutually exclusive. With flue spacers, ideal pallet placement is enforced by the flue spacers themselves. A quick, efficient method of pallet loading can be maintained while keeping flue spaces unobstructed and loads properly organized.

Complying with Local and National Codes

Wherever a warehouse is located, odds are it’ll need to comply with a combination of local, regional, and national safety codes. In many jurisdictions, these codes will mandate the use of flue spacers for the purpose of fire safety. While some codes may only require the use of flue spacers for rack systems over a certain height and others may not require them at all, it’s often better to err on the side of safety and install flue spacers.

Protection of Personnel and Product

This point is mostly self-explanatory, but still important to remember. There is nothing more important than protecting the people who work hard to move and store the product, which itself serves as the lifeblood of profit for the organization. Threats to the safety of workers and the potential for damage to product should be seen both as ethical problems and as risks to a company’s bottom line. Flue spacers offer an easy and cost effective opportunity to promote the wellbeing of both workers and a company’s material assets.

Ease of Use and Cost Effectiveness

Most models of Flue Spacers, including the WorldStop mentioned earlier, are very easy to install and relatively cost effective. Flue spacers and pallet stops usually come with hardware, and can easily be screwed into place. No fabrication or technical skill is required. With the help of an installation team, these accessories can be in place in short order. When considering the time and money that can be lost by not being proactive about safety, installing flue spacers becomes an even more cost effective decision. And, with a wide variety of sizes in production, the vast majority of warehouse operations can be accommodated.

If you find yourself skeptical of the need to use pallet rack safety accessories, pause and consider the potential benefits of implementing a given accessory, the risks of not doing so, and the actual cost. In some situations, the cost of using a safety product will negate the minimal-to-absent benefits of doing so. However, in many cases it will become obvious that there’s more to be gained than lost. In our experience, this is often the case with flue spacers.

Have more questions about flue spacers or need a quote for your customer? Give us a call at 888-578-1579 or email us at [email protected]!

What Flue Spacers and Pallet Stops Do

What Flue Spacers and Pallet Stops Do