There are different types of decks you can use on roll form, pallet rack beam levels. Wire decks work for customers most of the time, but there are occasions when they need flat decks as well. Customers may require this if they store carpet rolls or odd-sized items such as furniture or sliding hand-picked boxes on and off levels such as in Record Storage. We can provide different solutions to fit a customer’s requirements.

One way is to use safety bars underneath a metal flat cap. The safety bars are set into the step of the beam and provide the capacity for the beam level, while the flat cap solely provides the solid surface. The number of safety bars is determined by the capacity requirement and size of the material being stored. The safety bars are spaced to hold the load appropriately and screwed to the beam with a tek screw to ensure they remain in place.

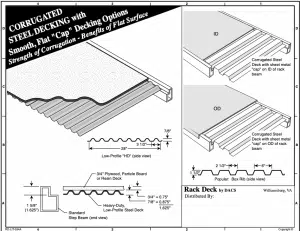

Another way is to use a corrugated deck under a flat cap. The corrugated deck is a ribbed deck that sits into the step of the beam. A tek screw is used to screw the beam into the deck. It provides a solid surface as well as the capacity needed to store material. Some customers choose to use only the corrugated deck. Others choose to put a flat cap on top so the ribbed material does not interfere with stored items.

Per fire safety codes, some pallet rack systems require sprinklers. Solid steel decks are not compliant with fire codes since they do not allow water drainage. These systems require perforated decks. These decks can be corrugated decks with holes used with a perforated flat cap for heavier loads or perforated rack decks for lighter loads.

Whenever using any of these flat deck options, it is essential to know the product dimensions, weight stored on each level, and permitting requirements. Concentrated loads (loads not uniformly distributed over the entire surface of the decking section), point loads (loads concentrated to particular points on the deck), and fire safety codes may require specific designs. Providing the right design ensures a safe warehouse.