What goes into the design of a wire deck?

• You must know what type of beams are in the pallet rack system.

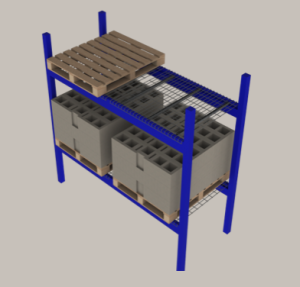

Beams and decks go together like hand and glove, so getting the right fit is necessary for safety and functionality. If your customer has a box beam, you could choose a universal box channel. It is placed directly on top of the beam and has a standard waterfall. If your customer has a tear drop step beam, then a U channel deck would work. There are many options to choose from and wire decks can be customized for your customer’s rack system as well.

• You must know what type of inventory your customer is storing.

Wire decking comes in all sorts of options from light duty, to standard, to super heavy duty. A typical wire deck has three to four support channels welded underneath to provide up to 2,500 lbs capacity. You need to be sure that the load bearing standards of the wire deck you choose will be sufficient for your customer’s inventory.

• You must educate your customer on how to properly load their wire deck.

It might seem tempting to just place inventory directly onto the deck, but unless what your customer is storing is relatively light, they must not load right onto the deck itself. Loading product directly onto the deck could fall under the categories of a point load, line load or concentrated load. These are all considered non uniformly distributed loads and not what wire deck is intended for. The inventory must be supported entirely by the front and rear pallet rack beams. Failure to adhere to this, could lead to failure of the deck itself, an unsafe warehouse environment and ultimately, an unhappy customer.

• You must know the environment of the wire deck.

Galvanized decking is the best option for wet, damp, refrigerator or outdoor settings. Even if the deck will be warm and dry inside, galvanized decking has its benefits. A galvanized finish stands up to repeated use and keeps its appearance and surface integrity. You can give your customer other options for finishes as well, such as powder coating and oven baked enamel.

Let our talented staff at WPRP help you to make the right choice for your customer and their wire decking needs. Our goal is to help you!