Sometimes we need to go back to the basics to help our dealers determine the best pallet rack storage solution for their customers. Often times this is as simple as determining the depth, height, and width of standard selective pallet rack bays. Below is a quick and easy guide you can keep on hand for the next time you need to calculate pallet rack dimensions:

Step 1: Determine Pallet Rack Width

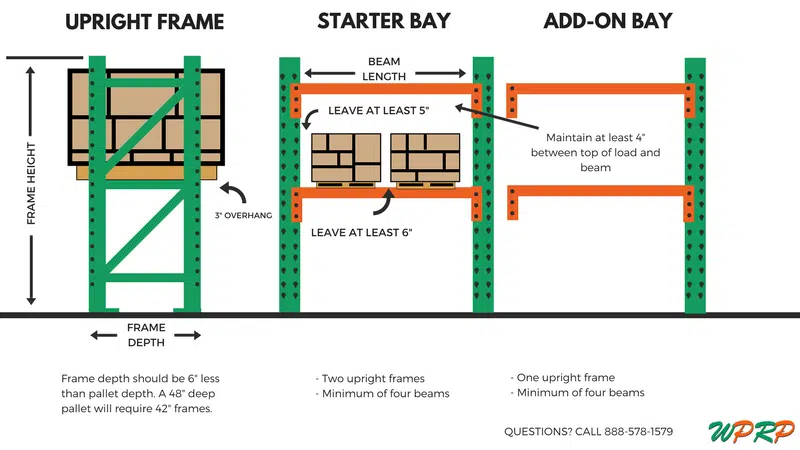

First, we’ll look at the required width of the bay. A standard GMA pallet is 40″ wide. In most applications, a forklift will require 5″ width between each frame and the pallet, as well as 6″ between the pallets on a double-wide bay to provide adequate space for loading and unloading the racking. This means we would take the width of the pallets (2 x 40″) and add 5″ + 6″ + 5″ to get the width requirement shown in the graphic above. In this case, we would require a 96″ bay width or beam length.

Step 2: Determine Pallet Rack Upright Depth

Second, we’ll determine the upright depth. A typical application requires the depth of an upright to be 6″ less than the depth of the pallet. For example, a standard GMA pallet is 48″ deep. The pallet should overhang the pallet rack beams by 3″ in the front of the racking and 3″ in the back of the racking. This overhang helps forklift operators make sure the pallet is resting fully on both pallet rack beams when loading. In this example, we would want 42″ deep uprights (48″ minus 6″).

Step 3: Determine Pallet Rack Upright Height

Third, we’re going to determine the required height of the upright. A 4″ minimum lift is required for a forklift to pick up and unload a pallet out of position in a pallet rack system. We’ll need to add this 4″ to the height of the load and include the pallet height in order to calculate the clear height required for each beam level. For example, if the load is 40″ tall (including the pallet) and we need 4″ for liftoff, our clear height requirement is 44″.

Next, we’ll need to factor in the height of the beam profile. In this example, we’ll use a 4″ high x 96″ long beam. We can add our clear height requirement (44″) to the height of the beam (4″) to figure out where the top of each beam level will be placed (levels at every 48″). If the customer required 2 beam levels in this example, we would have a top of beam level at 48″ and one at 96″. This means our minimum upright height requirement would be 96″. Depending on the application, you may choose to have a taller upright for additional growth or to prevent inventory from falling into aisles.

In the example above, we would provide our customer an upright that is 42″ deep, 96″ tall and 96″ wide. Now that you know how to measure pallet racking, you’re ready to determine the correct frame and beam capacity for your system.

If you have any questions on how to determine these dimensions for your pallet rack project, WPRP would be happy to help. You can contact us at 888-578-1579 or e-mail us.

Remember, our goal is to help you!