Selective pallet racking is the most basic form of modern industrial storage racking. Consisting of upright frames and cross beams, selective racking is simple and efficient in its design. Upright frames support the load beams, which in turn support the load being stored. This straightforward design must mean selective pallet racking is always easy to quote, right? Not so fast.

Like any material handling product, selective pallet racking needs to be quoted based on the needs of the end user. Load type, available space, capacity requirements, and the number of beam levels are all examples of information we need to know when quoting selective rack system. To help you get started with quoting selective racking, we’ve put together the guide below. By asking the questions listed below and learning to calculate dimension requirements, you’ll be well on your way to being a pro at quoting selective pallet rack.

How to Quote Selective Pallet Rack: Standard Questions We Ask Our Customers

“What material is being stored? What size is the material? Is it stored in individual boxes or on pallets? What are the overall width, depth, and height dimensions?”

“What will the weight of each box or pallet be?”

“How many boxes or pallets are required per level, and how many total levels will there be?”

“How much space is available for the pallet rack system?”

“Will the racking be up against a wall or near other obstructions, such as sprinkler systems?”

“Will the material be located outside, in a cooler, or in a corrosive environment?”

“Are any accessories — i.e. wire decks, column guards, safety bars, shims, anchors, etc. — required?”

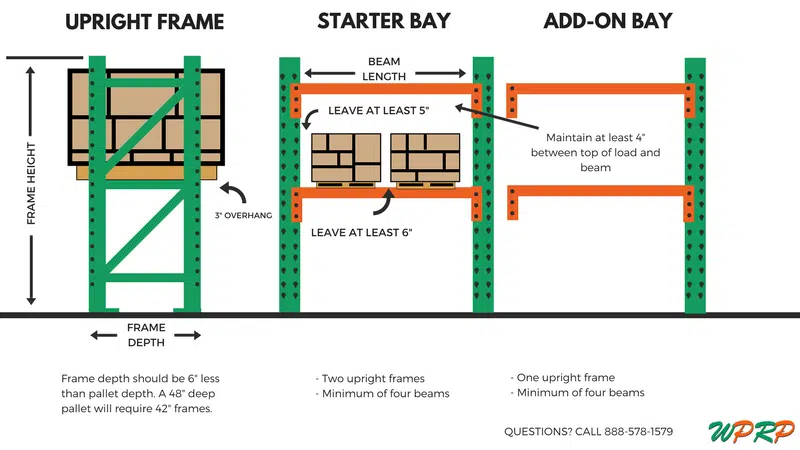

Pallet Rack Frame Depth

We’ll start off by looking at upright frame depth. Frame depth is typically 6” less than the depth of the pallet. This allows a 3” overhang on the front and rear of the system to help ensure the forklift driver sets the pallet on both beams. You can reference the diagram above for a simple illustration of what this should look like. For a more in-depth explanation of pallet rack dimensions, we encourage you to watch this video.

Pallet Rack Frame Height

Upright frame height is determined by four variables: Pallet height, beam profile height, and the number of beam levels. We’ll also need to add in 4″ for liftoff room for each beam level. Let’s take a look at an example case below:

Example case:

3 beam levels

40″ tall pallets

4″ beam profile

Example math: 40” pallet height + 4” beam profile + 4” liftoff = 48” first level. Add 48” second level + 48” third level = minimum 144” tall frame

Pallet Rack Beam Length

Beam length is determined by taking the number of pallets per level, multiplying that number by the width of the pallet, and adding a 5” space between the pallet and the frame on both ends and 6” of space between pallets.

Here’s an example of what this might look like in a real-world application:

Example case:

2 pallets per beam level

40” wide pallet

Example math: 5” space + 40” pallet + 6” space + 40” pallet + 5” space = 96” wide beam

Upright Frame Capacity

When quoting selective pallet racking, one of the most important things to get right is the capacity requirement. Underestimating pallet rack frame and/or beam capacity puts end users at undue risk. Fortunately, figuring out capacity requirements usually isn’t rocket science. Stick to the guidelines below and you’ll have a system for making sure you quote the right frames and beams for the job.

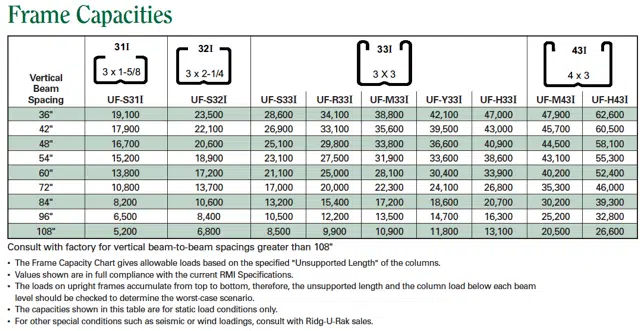

The required frame capacity is determined based on the maximum load per beam level, the number of beam levels per section, and the maximum vertical beam spacing (the distance from the top of one beam to the top of the next beam). To find the right frame column size, use the chart provided by the frame’s manufacturer. Below we have one from Ridg-U-Rak. First, multiply the weight per beam level by the number of beam levels per section of racking. Then, use the manufacturer chart to find the frame column you’ll need to hold that weight at the given beam spacing.

This can be a bit confusing at first, so take a look at the example provided to see this process in action.

Example case:

3 beam levels

2 pallets per level, each holding 2,500#

48” maximum vertical beam spacing

Example math: 2500# x 2 = 5000# per level x 3 levels = 15000# requirement per bay

In our example, a Ridg-U-Rak 31I frame column can be used because it provides 16,700# capacity

Beam Profile and Capacity

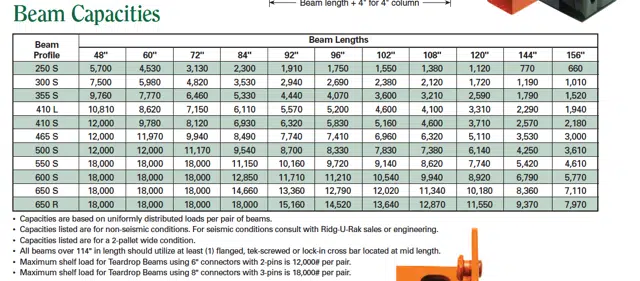

To determine the right beam profile, you’ll need to know the weight-per-pallet, the number of pallets per beam level, and the length of the beam being used. First, multiply the weight-per-pallet by the number of pallets per beam level. This number represents the total weight-per-beam level. Then, use a manufacturer chart like the one below from Ridg-U-Rak to determine which profile is needed to hold the total weight at a given beam length.

See our example for how this calculation would work with 96″ long beams and 2,500# pallet loads.

Example case:

2 pallets per level with 2500# per pallet

96” wide beam

Example math: 2500# x 2 = 5000# beam. Per the chart, we would need a 410 L beam profile for our application.

More Questions about Quoting Selective Pallet Racking?

At WPRP, our goal is to help you. If you have any questions about how to quote a selective pallet rack system, don’t hesitate to contact us. Our Pallet Rack Specialists are happy to help you through the quoting process.