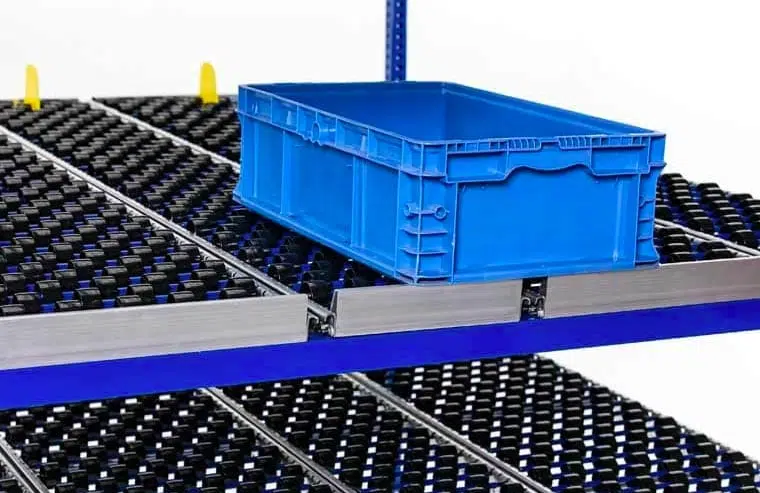

[flexy_breadcrumb] A Carton Flow Pallet Rack System is a FIFO (first in, first out) picking system that is a great solution for slow to medium moving SKUs. This gravity flow system utilizes inclined roller platforms that gently move the remaining cartons forward when the front carton has been picked.

A Carton Flow Pallet Rack System is an efficient way to store a high volume of inventory in less space. Racks can be consolidated to eliminate aisles, increasing floor space and maximizing warehouse storage capacity. With independently moving cartons, a carton flow system eliminates the time and labor needed to manually move cartons as needed on static rack systems. Cartons are always in the front position ready for full and/or split case picking.

Each carton flow system is custom-designed for the unique application and product. Carton flow can be implemented with pallet racking or as a stand-alone unit with a single row or many. Lane width, roller style, speed, and more are customized to best serve the application’s purpose.

Keep reading for more information about carton flow and how to quote these systems!

WPRP offers high-quality carton flow systems from the following manufacturers. Click each manufacturer logo to learn more about their products:

As mentioned, carton flow is for smaller loads stored in boxes or cartons. If a facility needs to keep both cartons and pallets, they can implement carton flow along with traditional pallet racking. Carton flow can also go on its own as a stand-alone unit. The amount of carton flow racking entirely depends on the product and purpose.

Carton flow is a gravity flow system that speeds the picking and packing process by minimizing the distance an employee needs to travel to reach a product. These systems bring the product to the picker, making things much easier and more efficient.

Warehouses that stock lots of the same product will benefit from carton flow and the high-density storage it offers. Carton flow is terrific for storing many products of the same SKU number in a single lane.

The design/manufacturing process for gravity flow systems is much more customized and entirely dependent on the product and pallet or carton. When designing a carton flow system, manufacturers will most likely request a loaded carton and create the system around the product exactly as it will reside in the warehouse.

Manufacturers must consider carton/box type, material, size, weight, and more because each factor plays into the system design and functionality. When quoting carton flow, it is essential to ask the right questions.

Following is the standard information we ask our customers when quoting a carton flow pallet rack system:

At WPRP, our goal is to help you. If you have additional questions about how to quote a carton flow pallet rack system, do not hesitate to contact us. Call 888-578-1579 or fill out a quote request form today to get in touch with a carton flow rack specialist.

Quick Ship.

Looking for Pallet Racking Quote out of Quick Ship? Fill out the form and a Pallet Rack Specialist

will contact you promptly.

Our multiple shipping points and network of manufacturers allow us to get your pallet rack products to you fast.