With WPRP University, our goal is to help you by getting back to the basics. We’ve found that a lot of the time, delivering value to your customer lies in being knowledgeable about the foundational parts of warehouse storage. It’s impossible to become a true expert without first having a firm grasp of things like how to measure frame depth, calculating the height-to-depth ratio, and, as we’ll cover in this article, the “when,” “how” and “why” of using pallet rack row spacers.

Even though the products, methods, and ideas we discuss in WPRP University are simple and straightforward, there are often deeper reasons for using them that are worth learning about in order to better understand that product and its function.

What is a Row Spacer?

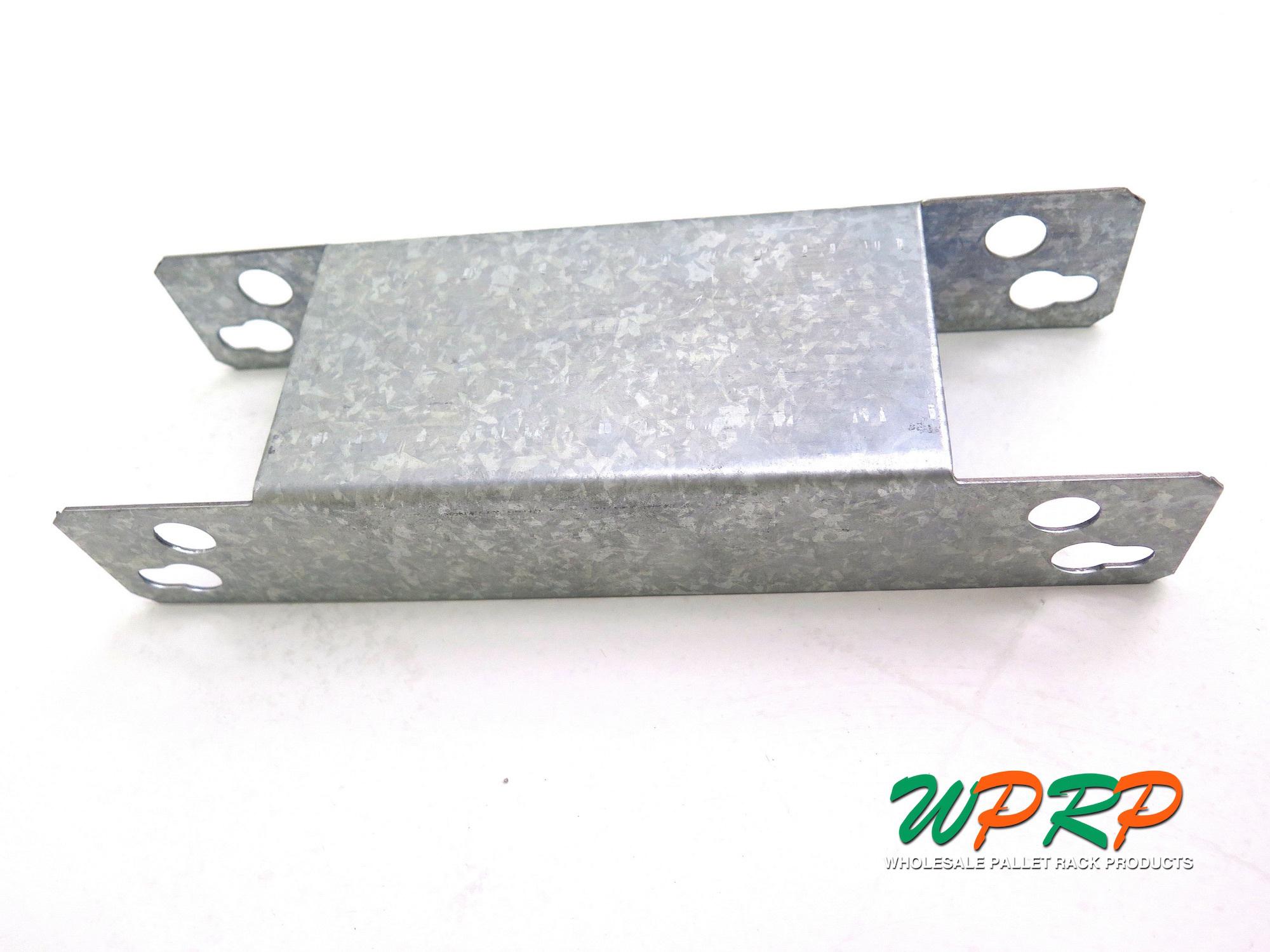

Row spacers are aptly named because their primary function is to keep a consistent horizontal distance between two rows of pallet racking. Row spacers come in a variety of shapes and sizes depending on who the manufacturer is. In the past, you could get them in a variety of colors, but now most manufacturers are producing a galvanized-finish row spacer, eliminating most alternate color options. The flat part in the middle of the row spacer is what is usually being referred to when referencing its length. Many row spacers have flanges that are screwed into the sides of the upright frames, and so this part of the row spacer can’t be included in the actual space between rows. See the image below for an example.

All row spacers share a common reason for existing: maintaining a certain amount of space between rows of pallet racking. Why is this important? As it turns out, there are a few reasons why row spacers are more important than many of us realize.

Why Would You Need Row Spacers?

Does every pallet rack application call for pallet rack row spacers? The short answer is “no.” An obvious example of an application without a need for row spacers is one with a single row of pallet rack. A job like this might require wall ties, but not row spacers, since there’s only one row, to begin with. Shorter racking systems that are bolted to the floor may also not call for row spacers since there’s less of an opportunity for the uprights to move. And although there are a lot of jobs in which row spacers would be unnecessary, there are also many warehouse storage applications out there that would benefit greatly from having them. There are a few main reasons why:

1. Row Spacers help keep longitudinal flue spaces clear.

If you or your client owns or operates a warehouse, odds are you want to be code compliant. Not only does being code compliant generally improve the overall safety of the workplace, but it’s the best way to avoid being stung by a violation fine. By keeping pallet rack rows a minimum distance apart from one another, row spacers eliminate the need to worry about longitudinal flue spaces. Note: Be sure to install row spacers that are long enough. If codes mandate 6” longitudinal flue spaces, a 6” row spacer isn’t likely to cut it, because the 3” of pallet overhang on each side will fully eclipse the 6”, leaving your flue space at roughly 0”.

2. Row spacers can effectively double the depth of the uprights.

We’ve discussed the importance of having a safe height-to-depth ratio. ANSI/RMI recommends normal anchoring for racks with a height-to-depth ratio of 6 to 1 or less. If higher than that, anchoring that resists at least 350# of force at the top level is required. However, row spacers can also be used to connect two rows of racking that would otherwise have height-to-depth ratios over 6 to 1, effectively lowering their height-to-depth ratio and stabilizing the system.

3. Row spacers keep pallet rack rows aligned.

If it’s particularly important to keep a consistent space between back-to-back rows of pallet racking in a warehouse, row spacers are often the easiest and most cost-effective way of doing it. By adding one or more row spacers per upright column, it’s possible to keep both rows plumb throughout the distance of the racking system.

What Do I Need To Consider When Purchasing Row Spacers?

1. Compatibility

Certain row spacers are compatible across different styles of pallet racking. The row spacer pictured at the beginning of this post is a Ridg-U-Rak row spacer and is compatible with both teardrop and slotted pallet rack. Some row spacers may be compatible with only roll-formed or structural. It is important to know what type of pallet rack the customer has, if they don’t already, in order to inform your purchasing decision. Here’s a helpful chart from Ridg-U-Rak to help guide compatibility questions.

2. Row Spacers Per Upright

This goes back to the height of the racking. The following are manufacturer’s guidelines for the number of row spacers per frame:

- For uprights 4 – 14 ft. – minimum of one row spacer

- For uprights 15 – 24 ft. – minimum of two row spacers

- For uprights 25 – 34 ft. – minimum of three row spacers

It is important that the row spacers are installed near the top horizontal brace of the upright, and that there is no more than 10 feet between row spacers.

3. Placement and Installation

Once the proper type and number of row spacers have been purchased, proper installation is crucial.

- Install the bottom row spacer at least 5″ from the floor

- Install the top row spacer next to the highest horizontal strut

- Install the intermediate row spacers next to the strut connections, while maintaining equal distances between them of no more than 144”

- Be sure to avoid interference with struts, rack beams, and other components.

Where to Find Pallet Rack Row Spacers

If you find yourself or your customer in need of pallet rack row spacers, you won’t have to look far. The often-overlooked pallet rack row spacer is still an important facet of warehouses around the globe, and it’s common to find it in the inventory of material handling equipment distributors. That’s why we stock it as part of our 48 Hour Quick Ship program, and why we encourage our customers to keep row spacers in mind. You never know when your customer will need a cost-effective way to meet safety codes, improve the stability of their racking, or just keep everything in line.

If you’d like to learn more about row spacers, please give us a call or send us an email and ask away.

More Row Spacer Resources from WPRP

Remember, our goal is to help you!