What to Ask When Quoting Replacement Upright Frames

How many times have you been asked to quote replacement frames by a customer? We encounter it all the time ourselves, and it’s not always obvious what they actually need. Are they looking for a whole bay, or just a single upright? Do they need a standard teardrop frame to fit their existing racking, or do they require a specific brand? Of course, it’s critical to make sure the upright you’re providing will meet their needs in terms of both functionality and appearance. Providing a frame made by the wrong manufacturer could result in decreased capacity or overall performance in certain scenarios, and not matching the current color scheme can rub certain customers the wrong way. At WPRP, we’re proponents of checklists and other failsafes that allow us to cover all of our bases without the need to jog our memories or ask around each time. As always, we want to pass this information along to you, so we’ve put together a basic checklist that can help you determine the right fit and product when quoting replacement upright frames.

Quoting Replacement Uprights

When you’re quoting replacement uprights, you’ll want to ask each of the questions below. Don’t skip any of them, as they’re all going to provide pieces of information you’ll consider when choosing what kind of frame to offer in a given situation.

Checklist:

- Ask for the Load Information

When we say load information, we’re referring to the dimensions and properties of the product or other items that will be stored on the racking. We want to find the answers to important questions about the racking’s load: How much will it weigh? What is the length, width and height of the load for a given pallet position? Neglecting the consideration of this information can result in a failure of the racking to serve its main purpose: storing heavy product above the ground.

2. Beam spacing and Beam Level Elevations.

Beam spacing and elevation is an essential part of pallet rack performance, particularly in applications with heavy loads. As a rule of thumb, the frame capacity (the overall amount of weight a frame can support in a pallet rack bay) will go up as the beam spacing (the vertical space between two beam levels) goes down. This can be demonstrated by flexing an uncooked spaghetti noodle and observing the deflection, then breaking the noodle into a one inch piece and replicating the action with the smaller piece. Applications with heavy loads and large beam spacing will often require sturdier upright frames than lighter duty storage applications with standard or smaller beam spacing.

3. Weight Supported per Beam Level.

We touched on weight briefly in the first point, but weight-per-beam-level deserves its own bullet point. The weight supported by each beam level is important to know, as it factors into the overall weight supported by the upright frames. It’s not necessarily as easy as doubling the weight per pallet position from the item on the list, because there’s no guarantee that the weight carried on a beam level will be evenly distributed. It’s also critical to ask whether or not the load will actually be sitting on both beams. If it is not, it may require both heavier beams and heavier wire decks, depending upon the weight of the load.

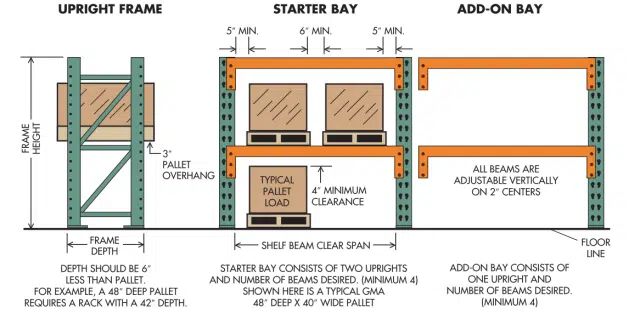

4. Depth and Height of Existing Uprights

Of course, you’ll want to know the dimensions of the existing frames so that you can match them if possible. Even if you’re unable to match brands precisely, matching dimensions can go a long way towards meeting the end user’s needs if they’re simply looking for functionality. The depth of the upright frame must match that of the existing frames, and the upright column dimensions will dictate the column’s, and therefore the frame’s overall capacity.

5. Pictures of the Existing Pallet Racking.

Sometimes pictures can answer questions that would take dozens of emails or phone calls to figure out. Kickstart your replacement upright project by obtaining pictures that can be used to identify useful information about the product, such as brand, size, color, punch style, etc.

Need help identifying your racking? Be sure to bookmark our rack identifier. If you need a hand tracking down an upright frame for a project, reach out to us via email at [email protected] or by phone at 888-578-1579