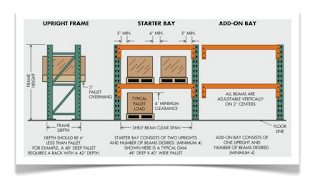

Transverse flue space = the space to either side of a pallet in a storage system. Typically, this space should measure a minimum of 3 inches. In the picture below, the transverse flue space is measured at 5 and 6 inches.

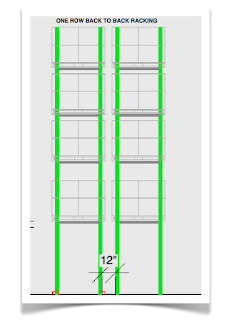

Longitudinal flue space = the space between rows of back-to-back racking. Typically, the longitudinal flue space is a minimum of 6 inches between the loads. This distance between the racks should be even greater because it will include the minimum of 6 inches between the loads as well as the load overhang which is typically 3 inches for each back-to-back bay as shown in the picture below.

If you have any questions regarding flue spaces, tell us about your next project we will be happy to help!

Source: http://www.wikimheda.org/wiki/Transverse_flue_space, http://www.wikimheda.org/wiki/Longitudinal_flue_space